Jun . 13, 2024 11:01 Back to list

Volvo manufacturing facilities for home charging stations

The Realm of Volvo Home Charging Points A Manufacturing Perspective

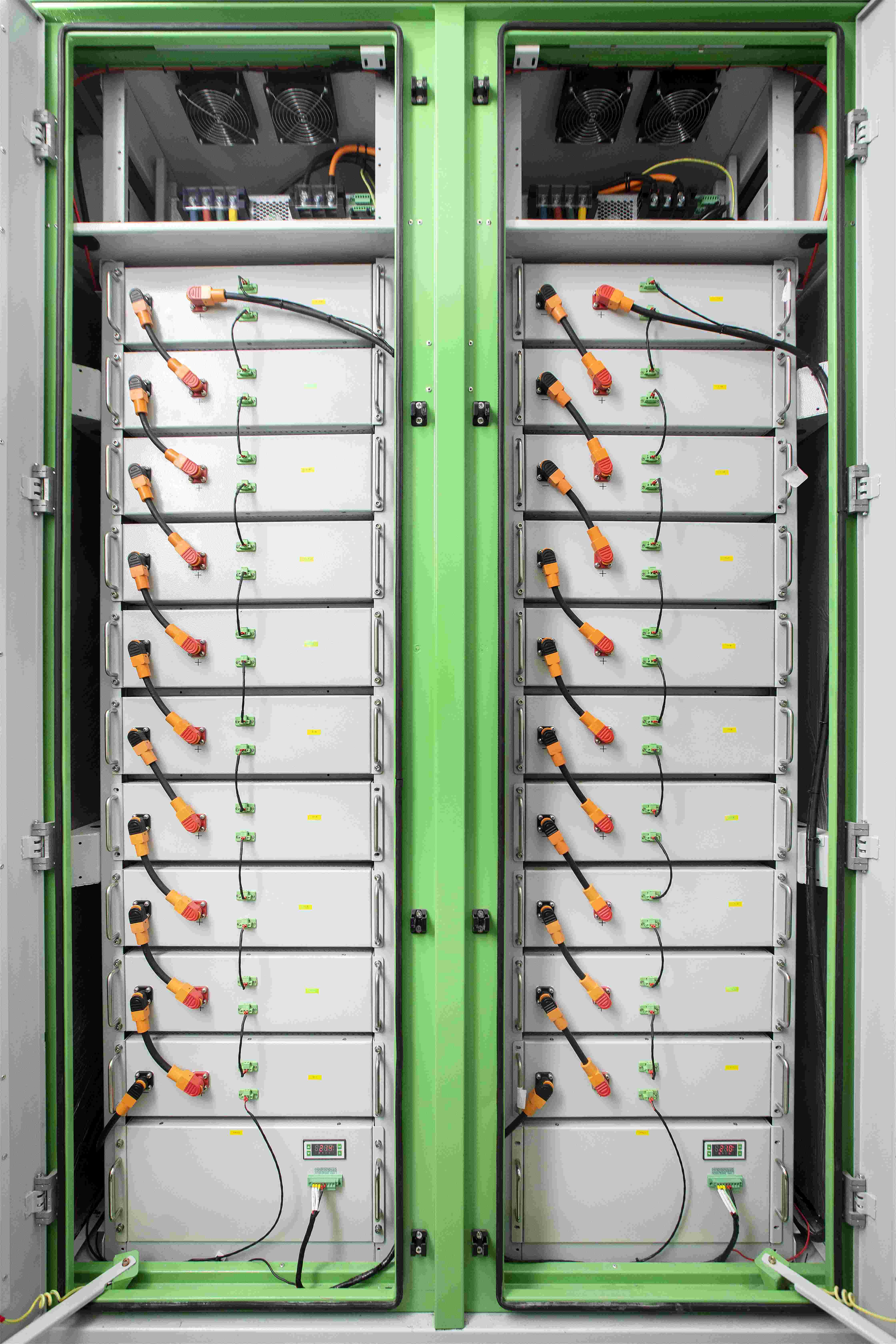

Volvo, the renowned Swedish automotive giant, has been at the forefront of the electric vehicle revolution, not just in terms of vehicle design but also in infrastructure development. One key aspect of this transition is the Volvo Home Charging Point, an innovative solution that facilitates seamless charging for electric vehicles right at home. This article delves into the factories where these charging points are manufactured, showcasing the precision engineering and sustainable practices that define Volvo's commitment to the future of mobility.

Volvo's home charging point factories are scattered across various locations globally, each one echoing the company's dedication to quality and environmental sustainability. These facilities are not just manufacturing hubs; they are centers of technological advancement and eco-conscious production.

The manufacturing process begins with the selection of materials. Volvo prioritizes recyclable and durable components, reflecting its 'Design for Disassembly' philosophy. The charging points are made from high-strength steel and advanced plastics, ensuring both resilience and minimal environmental impact.

In these factories, automation and robotics play a crucial role in precision assembly. State-of-the-art machinery handles tasks like welding, assembly, and testing, ensuring consistent quality and efficiency. However, human expertise remains integral, overseeing the entire process and ensuring that every charging point meets Volvo's stringent safety and performance standards.

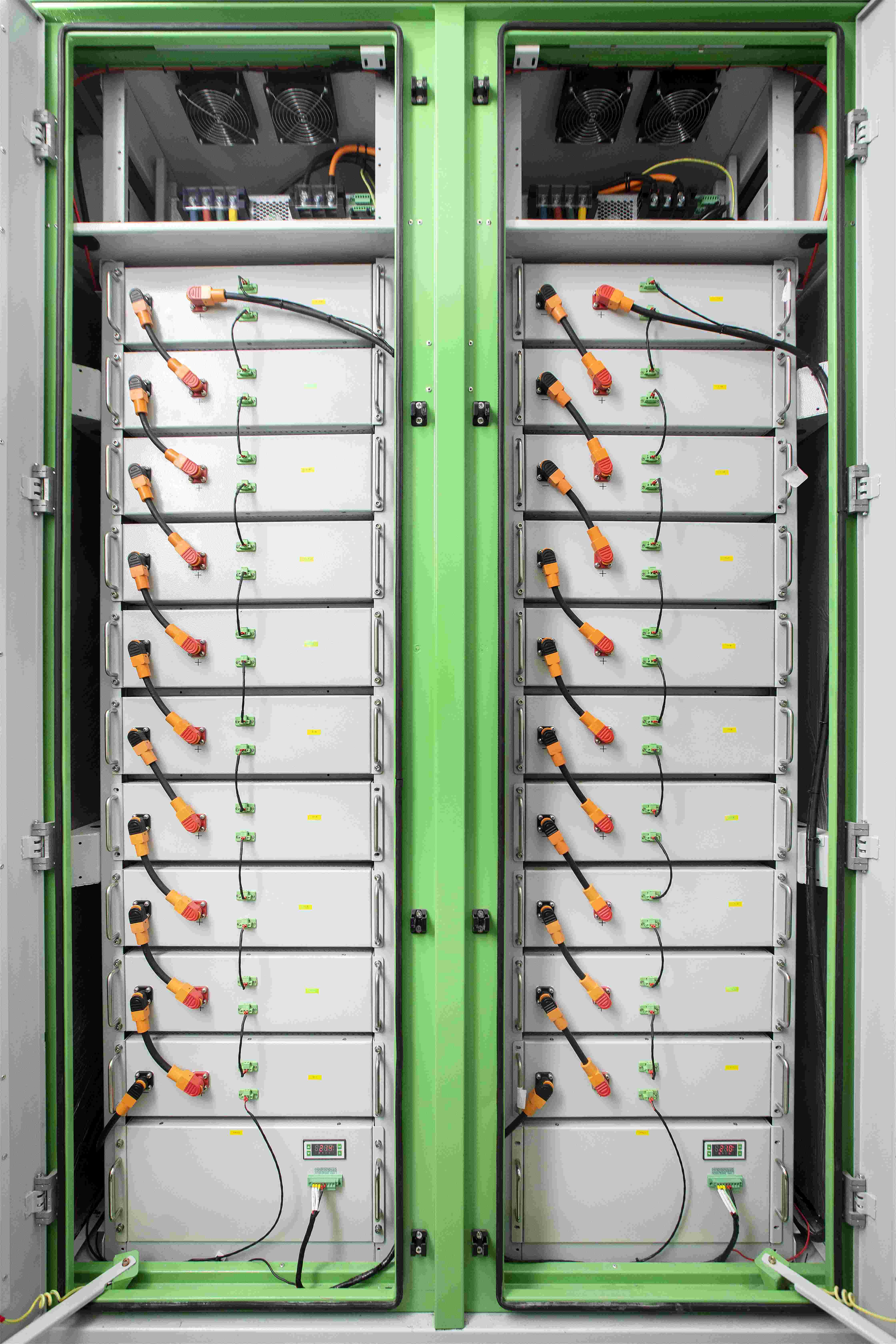

Energy efficiency is another core principle. The factories incorporate renewable energy sources like solar panels and wind turbines, significantly reducing their carbon footprint. Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach

Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach volvo home charging point factories.

Quality control is rigorous. Each charging point undergoes multiple rounds of testing, simulating real-world conditions to guarantee reliability and safety. This includes tests for waterproofing, durability, and compatibility with various electric vehicle models.

Moreover, the factories are designed with ergonomics and employee well-being in mind. Open layouts, natural lighting, and ergonomic workstations foster a safe and healthy working environment. Volvo's commitment to its workforce is a testament to its holistic approach towards sustainability.

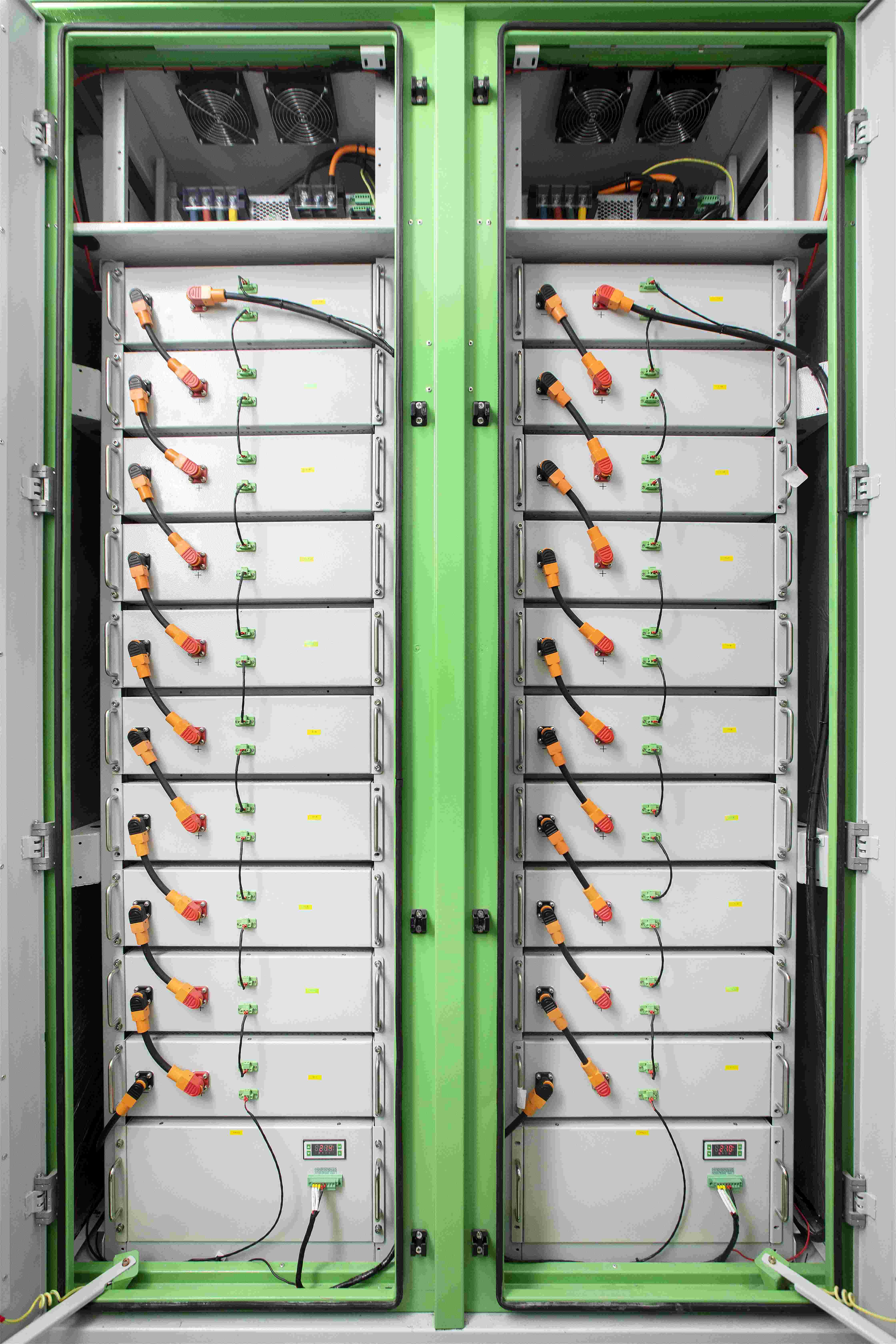

Beyond the physical product, the home charging points come with user-friendly digital solutions. These integrate seamlessly with Volvo's connected car services, allowing owners to monitor and manage their charging remotely. It’s a testament to Volvo's vision of a future where technology enhances the driving experience.

In conclusion, the manufacturing of Volvo Home Charging Points is a symphony of advanced technology, sustainable practices, and ergonomic design. These factories represent more than just production lines; they embody Volvo's commitment to innovation, sustainability, and customer-centricity. As the world moves towards electrification, Volvo's home charging points, born in these factories, stand as a beacon of convenience, reliability, and environmental responsibility.

volvo home charging point factories.

Quality control is rigorous. Each charging point undergoes multiple rounds of testing, simulating real-world conditions to guarantee reliability and safety. This includes tests for waterproofing, durability, and compatibility with various electric vehicle models.

Moreover, the factories are designed with ergonomics and employee well-being in mind. Open layouts, natural lighting, and ergonomic workstations foster a safe and healthy working environment. Volvo's commitment to its workforce is a testament to its holistic approach towards sustainability.

Beyond the physical product, the home charging points come with user-friendly digital solutions. These integrate seamlessly with Volvo's connected car services, allowing owners to monitor and manage their charging remotely. It’s a testament to Volvo's vision of a future where technology enhances the driving experience.

In conclusion, the manufacturing of Volvo Home Charging Points is a symphony of advanced technology, sustainable practices, and ergonomic design. These factories represent more than just production lines; they embody Volvo's commitment to innovation, sustainability, and customer-centricity. As the world moves towards electrification, Volvo's home charging points, born in these factories, stand as a beacon of convenience, reliability, and environmental responsibility.

Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach

Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach Waste management systems are in place to recycle and reuse materials wherever possible, aligning with Volvo's circular economy approach volvo home charging point factories.

Quality control is rigorous. Each charging point undergoes multiple rounds of testing, simulating real-world conditions to guarantee reliability and safety. This includes tests for waterproofing, durability, and compatibility with various electric vehicle models.

Moreover, the factories are designed with ergonomics and employee well-being in mind. Open layouts, natural lighting, and ergonomic workstations foster a safe and healthy working environment. Volvo's commitment to its workforce is a testament to its holistic approach towards sustainability.

Beyond the physical product, the home charging points come with user-friendly digital solutions. These integrate seamlessly with Volvo's connected car services, allowing owners to monitor and manage their charging remotely. It’s a testament to Volvo's vision of a future where technology enhances the driving experience.

In conclusion, the manufacturing of Volvo Home Charging Points is a symphony of advanced technology, sustainable practices, and ergonomic design. These factories represent more than just production lines; they embody Volvo's commitment to innovation, sustainability, and customer-centricity. As the world moves towards electrification, Volvo's home charging points, born in these factories, stand as a beacon of convenience, reliability, and environmental responsibility.

volvo home charging point factories.

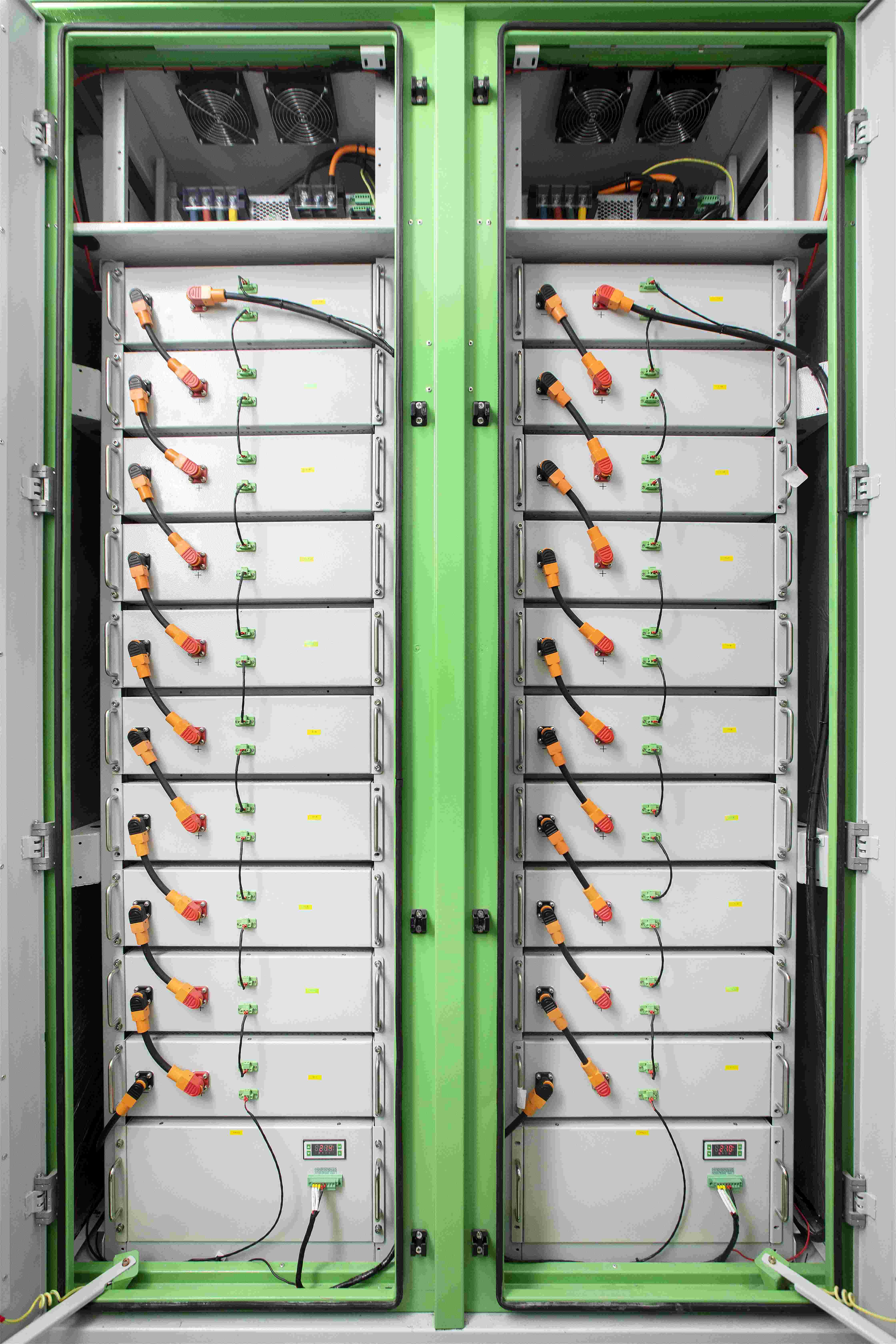

Quality control is rigorous. Each charging point undergoes multiple rounds of testing, simulating real-world conditions to guarantee reliability and safety. This includes tests for waterproofing, durability, and compatibility with various electric vehicle models.

Moreover, the factories are designed with ergonomics and employee well-being in mind. Open layouts, natural lighting, and ergonomic workstations foster a safe and healthy working environment. Volvo's commitment to its workforce is a testament to its holistic approach towards sustainability.

Beyond the physical product, the home charging points come with user-friendly digital solutions. These integrate seamlessly with Volvo's connected car services, allowing owners to monitor and manage their charging remotely. It’s a testament to Volvo's vision of a future where technology enhances the driving experience.

In conclusion, the manufacturing of Volvo Home Charging Points is a symphony of advanced technology, sustainable practices, and ergonomic design. These factories represent more than just production lines; they embody Volvo's commitment to innovation, sustainability, and customer-centricity. As the world moves towards electrification, Volvo's home charging points, born in these factories, stand as a beacon of convenience, reliability, and environmental responsibility. Latest news

-

Advanced AI Energy Management with GPT-4 Turbo

NewsAug.02,2025

-

AI-Powered EMS with GPT-4-Turbo | Efficiency Boost

NewsAug.01,2025

-

Optimized Storage System for GPT-4-Turbo | High Performance

NewsJul.31,2025

-

AI Energy Management System w/ GPT-4 Turbo Efficiency

NewsJul.31,2025

-

High-Performance Energy Storage System for Reliable Power Solutions

NewsJul.30,2025

-

Advanced EMS Solutions for Energy Management System & Storage Battery Companies

NewsJul.29,2025